Interfaces

Are you looking for a clever solution that gives you fast and independent access to your renewable power plant data? A solution that furthermore has an integrated data-processing engine for intelligent Portfolio- and Performance Management and eases you into the „Big Data“ world?

Are you tired of fighting your way through a raw-data jungle, limited OEM, cloud or other third-party solutions to support your O&M and Asset Management? Do you need a fast and robust solution that remains cool in the face of IT-system hiccups and won’t collapse your communications network?

We’ve got just the solution for you, at a fair price with a short payback period.

The solution

n7® BI Appliance

The n7® BI Appliance is an innovative power-plant solution that increases your data availability and raises your analysis and reporting capabilities to a new level. The n7® BI Appliance is a marriage of our high-performance birdy7® BI Plattform with robust industrial hardware. It can be installed directly in your power plant infrastructure, either as 19” rackable unit, or as a flexible, compact PC equipped with a magnetic mounting system.

In detail

Fast access to huge data volumes

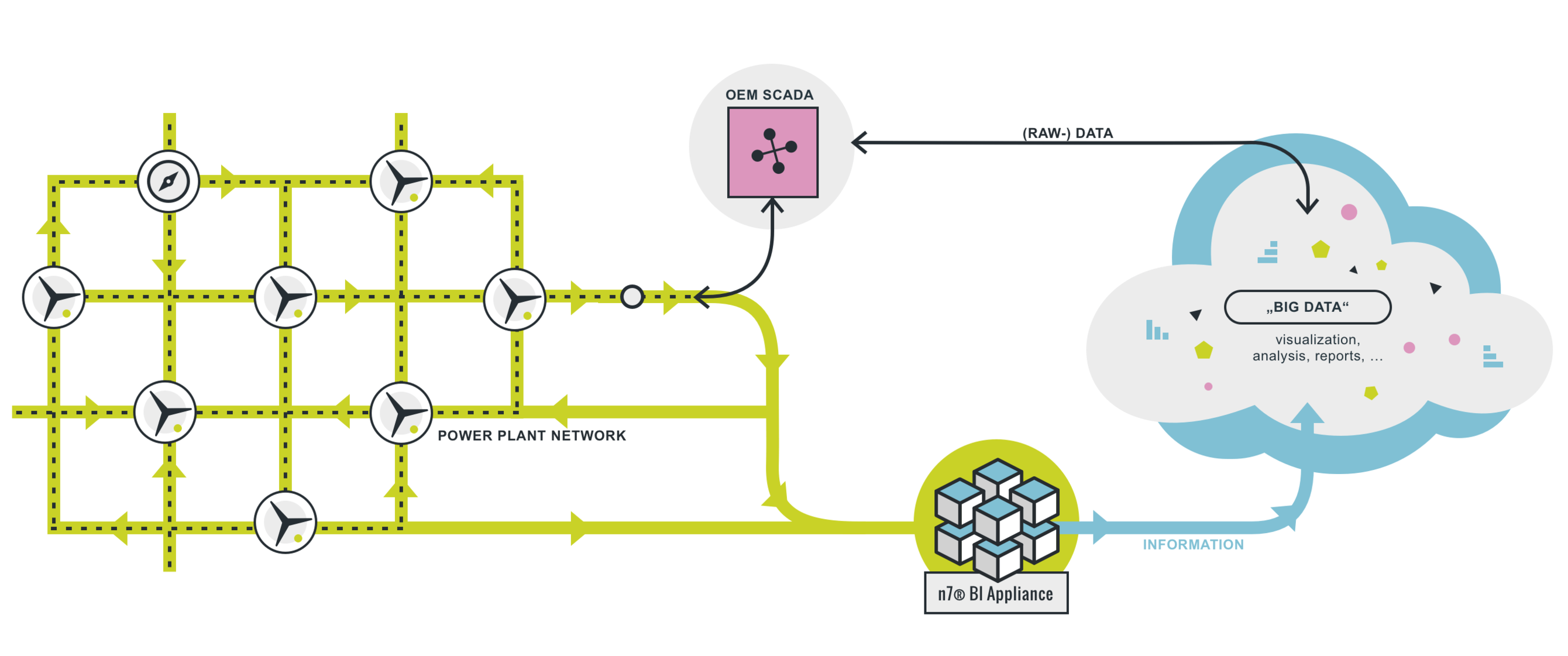

The n7® BI Appliance collects the data directly from your installed systems; be it wind turbines, met towers or transformers. It therefore becomes irrelevant whether or not your OEM SCADA system is functioning properly, or whether a turbine PC is on the blink. Since the data traffic on your network is not affected, your access to data remains unhindered. The n7® BI Appliance comes with a configurable data buffer, allowing it to continuously deliver and process the large data volumes it was designed for. This direct connection to your unit operations furthermore makes you independent of your OEM SCADA system. As a pleasant side-effect, you get more freedom over the extent of the signals you can monitor, and even more control over your power plant data.

Business-Intelligence for your power plant

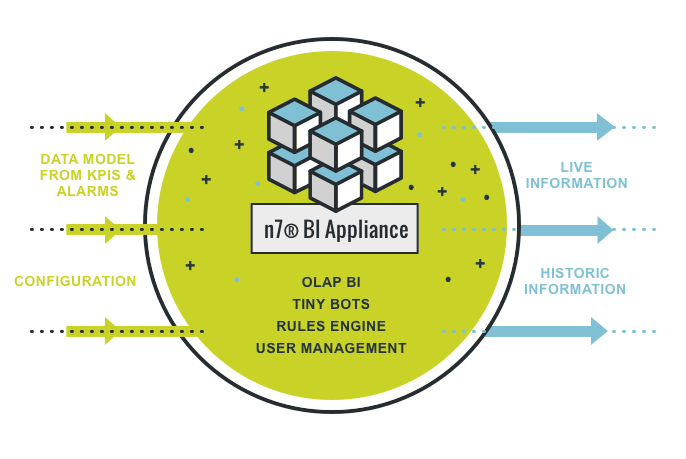

The installation of the n7® BI Appliance gives your power plant a new form of business intelligence. For this you can thank the birdy7® BI Plattform with its integrated OLAP Server. Compared to traditional interfaces such as OPC XML-DA and SQL-databases, the n7® BI Appliance not only provide you with raw data, but collects, processes and enriches your power plant data in situ. Which data it should collect, what queries to make and which analyses it needs to perform is up to you to decide and to configure. Define your own KPIs and analytic tasks, and create customized alarm categories with the built-in Rule Engine. The cool thing is, our universal data model allows you to make comparisons across your entire fleet, irrespective of energy technology. With the n7® BI Appliance, your power plant data is transformed in-situ to valuable information that boost your decision-making capabilities.

Flexible post-processing of your power plant data

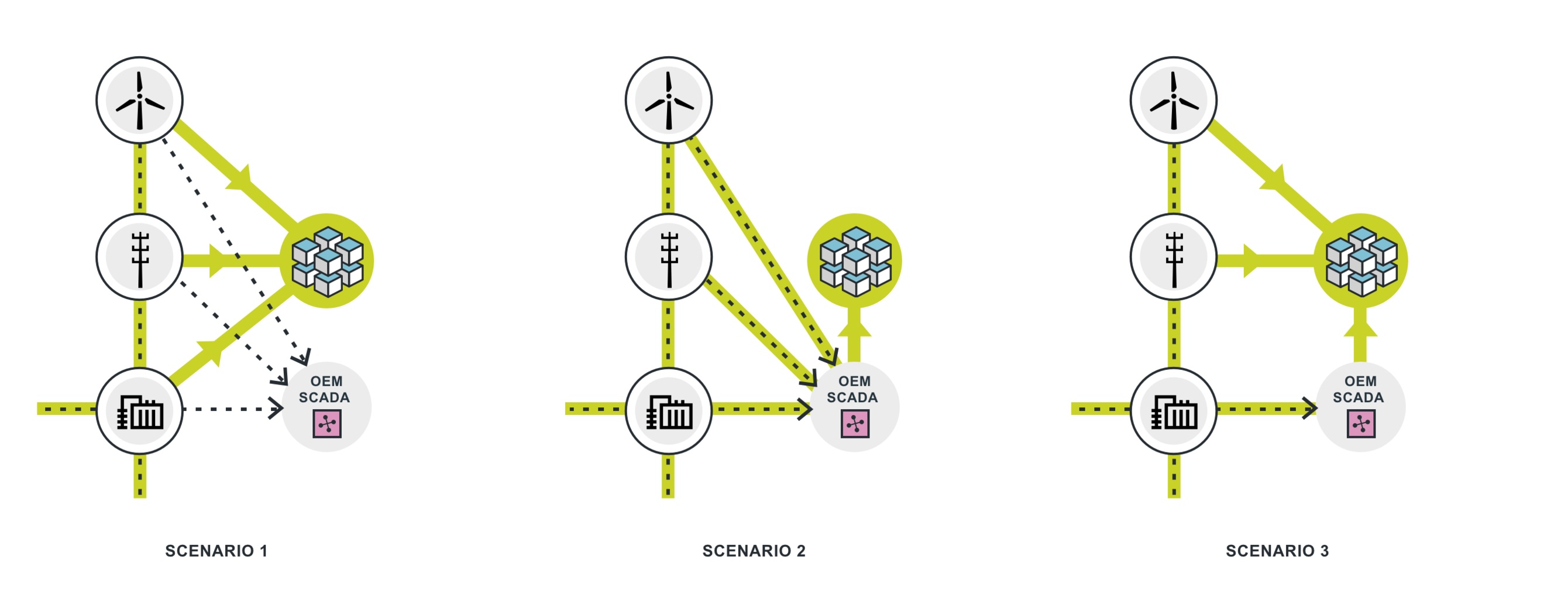

Your data is collected and processed inside the framework of our flexible, universal data model and carefully prepared for high-level post-processing with third-party tools. You can integrate the processed data seamlessly into your existing Cloud solution, your power-plant management software or in the advanced birdy7® Fleet Management. Nothing prevents you from also using the BI for enriching the analysis and reporting in other applications. This allows you to implement urgently-needed analytics even if your existing Cloud solution or management software does not support these analytics. If you choose an expansion to 1st/2nd Level SCADA, you can also use the n7® BI Appliance parallel-, or as an alternative to your OEM SCADA system. This enriches your data functionality and enhances your data resilience at the same time. We’ll gladly consult you on the various scenarios available to you.

Future-proof your power plant

This innovative solution prepares your power plant for the future. Your data travels in the most direct way and arrives on your desktop already prepared and analyzed. Whether you’re collecting, processing or analyzing, the n7® BI Appliance paves the way for your power plant to enter the „Big Data“ world. Irrespective of whether you’re managing alarms, doing root-causes analysis or making predictions / forecasts, the enhanced data quality brought to you by the n7® BI Appliance helps you to increase the performance and enhance the profitability of your investment.

Interface, manufacturer & technology-independent

Our flexible data model enables you to connect diverse power plant types; be it wind, hydro or solar power. With more than 900 SCADA Systems worldwide and over 17 years of experience in the field, we are able to equip Nordex wind power plants quickly with the n7® BI Appliance. Do you have wind farms from other manufacturers like Vestas, Siemens Gamesa, GE Wind Energy, Enercon, Goldwind or Senvion? Do you want to equip these wind farms with the n7® BI Appliance but continue to use your existing interfaces? Talk to us - we’ll show you the way.

| Basic | Advanced | |

|---|---|---|

| Hardware | ||

| Fanless industrial box PC | ✓ | |

| 2 TB industrial SSD for medium-term data storage | ✓ | |

| 19” industrial fan-cooled PC (4U) | ✓ | |

| 3x2 TB industrial SSD configured as RAID5 for long-term data storage | ✓ | |

| Siemens hardware (or comparable manufacturer) | ✓ | ✓ |

| Retrieval and collection of all data | ||

| End-to-end TLS 1.2 encryption | ✓ | ✓ |

| Remains online even with weak internet connection | ✓ | ✓ |

| Highly-compressed data assembly | ✓ | ✓ |

| All standardized industrial protocols such as OPC-XML DA, OPC UA, OPC-DA, Modbus, IEC 60870-104, IEC 61400-25 and more | ✓ | ✓ |

| OLAP services and APIs | ||

| Highly-compressed persistance of your data | ✓ | ✓ |

| Extremely fast access times | ✓ | ✓ |

| Persistence of calculated values such as availability or theoretical power | ✓ | ✓ |

| Incremental OLAP-data is continously written to the OLAP server and available instantly | ✓ | ✓ |

| Rule engine for creating individualized alarms/events and -categories | ✓ | ✓ |

| Efficient monitoring, since only changes in data are transmitted | ✓ | ✓ |

| Attachment of external diagnostics tools to the OLAP-Server, e.g. Tableau | ✓ | ✓ |

| Abstract data model | ||

| Integration of diverse data sources to an abstract data model | ✓ | ✓ |

| Individualized refresh rate to match your needs and hardware capability | ✓ | ✓ |

| Individualized archiving intervals to match your needs and hardware capacity | ✓ | ✓ |

| Comprehensive analysis and reports on fleet level | ✓ | ✓ |